Passion and expertise at your service

Research and development

OMET Systems in Motion has always invested heavily in research and development to create future-oriented products and to provide customers with innovative handling solutions and increasing efficiency. Research is carried out in collaboration with the customers, suppliers, research entities, companies, laboratories and institutions. OMET works in partnership with the customer to identify the best solution in terms of quality, performance, functionality and cost. Moulds, machinery and products are designed, engineered and refined using innovative software tools.

OMET offers customised solutions ranging from the simple steel bearing to assemblies: it has extensive expertise in the use of plastics and invests on new material testing. Great design capacity, flexibility and great technical expertise are its trump cards. The result is products which are more precise, more efficient and more silent. Able to adapt more and more to complex operating conditions and critical environments. Relying on OMET means having guaranteed innovation, safety and competitiveness. Optimised efficiency derives from calculation and simulation activities, studying materials and developing prototypes and performing tests, evaluations and improvements.

Laboratory & testing

Every OMET product is tried and tested individually. Specific equipment, created thanks to the internal engineering, simulates the conditions of use that the product will be subjected to, with wear tests and customised tests performed on the application that the customer provides. OMET has set up testing laboratories with modern equipment in Italy as well as in China for static and dynamic load tests. Tests performed on the bearings range from simulation of loads from axial and radial aspects and verification of performance in relation to the number of revolutions and the speed of rotation; and also the cyclicity tests with rotary movement in both directions, alternating or continuous.

Equipment with a salt spray chamber (SST Salt Spray Test) is used to perform NSS tests (pH-neutral resistance), AASS tests (PH acid resistance) and CASS tests (tests with temperature changing cycles), the latter being particularly common in the automotive sector, to check the tightness of the anti-corrosive surface treatment of the products, which are to be used in environments with high humidity. Specific tests are performed on all products.

Collaborations

Collaboration with research institutes and universities enables OMET to develop new process and product solutions to enhance the efficiency and quality of its products.

Working in partnership with customers and specialised suppliers creates positive synergies starting from different expertise, allowing to fulfil the most demanding requirements with a continuous process of improvement and innovation.

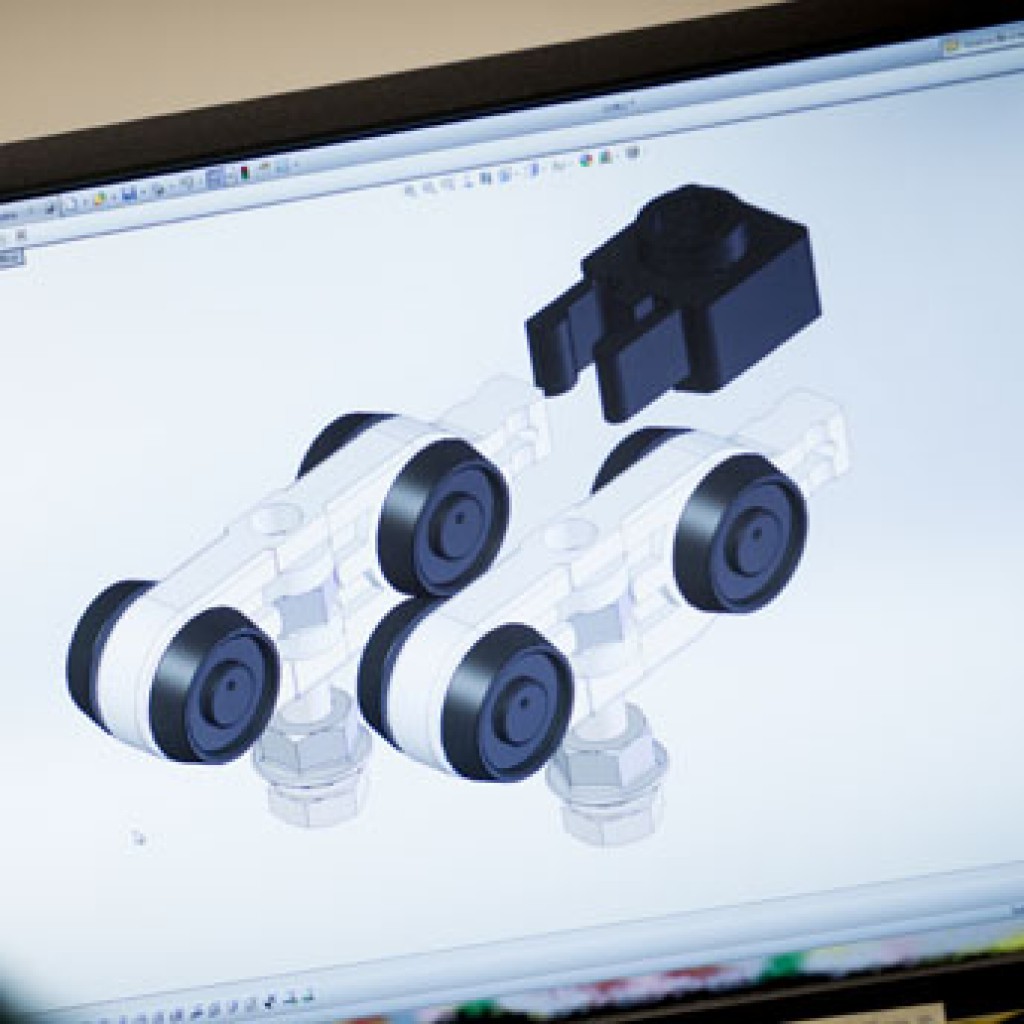

3D design

The design activity is the core and the starting point of the product development cycle. The OMET Systems in Motion technical department uses the most advanced 3D design systems with a sintering process to develop the customer’s requests and a product prototype, choosing the most suitable materials and defining the most appropriate processes to guarantee the highest competitiveness to its customer.

Logistics and Traceability

Each OMET product is packaged and delivered according to just-in-time logic, stock or kanban and is fully traceable. Total quality guaranteed, regardless if produced in Italy or in China. Specific procedures allow the finished and semi-finished products to be identified along the entire production process, as from acceptance using visual methods and computer records that provide information on the status of the goods and the conditions of use. In practice, they trace the ‘personal’ history. The process is completed in the packaging and storage phase: the information on the labels allow OMET to trace the raw material from the finished product, thereby providing the client with the entire documentation on the checks performed accordingly.

In this sense, the choice made over fifteen years ago assumes its primary reason for being, that of adapting the company management system to the European standard UNI-EN ISO 9000. Among the aspects that distinguish Omet from its competition lies the logistic organisation, with the possibility of kanban delivery, i.e. weekly product pick-ups from our warehouse, thereby allowing customers to operate with a just-in-time strategy.

Italiano

Italiano

简体中文

简体中文