Overhead conveyors

The use of overhead conveyors in industry stems from the need to exploiting all the space available in production buildings, moving the dimensions of the transport systems from the floor to the ceiling.

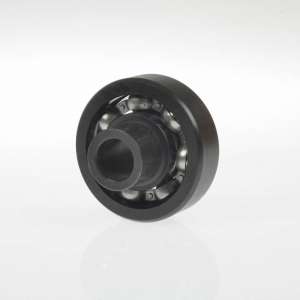

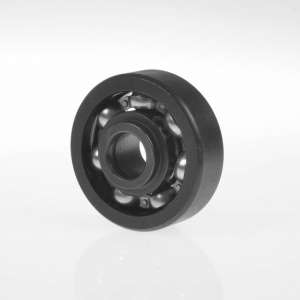

OMET bearings guarantee excellent resistance and fluidity in all overhead chains, suitable to transport hanging products, which may be very heavy, both horizontally and vertically. They can be turned, moulded, ground and made of different materials: 100CR6, carbon steel, alloy steel and stainless steel.

The bearings for overhead conveyors are available in different versions for specific usage requirements: with sintered and riveted cages, fully filled and single or double row.

One of the critical factors to develop excellent handling solutions in this sector is the grease: OMET is developing specific studies and research on the subject to provide top quality and fluidity of grease-free bearings or others made with special grease, which can withstand and function perfectly even in harsh environments, at high temperatures and in corrosive environments.

Even in this sector, OMET designs custom solutions together with the customer. The bearings for overhead conveyors are available in different versions for specific usage requirements: with sintered and riveted cages, fully filled and single or double row.

If bearings are fitted on overhead chains that require particular silence, coatings made of various materials can be applied so as to obtain the intended result.

Do you know that...?

Applications of overhead chains are much more widespread than one can imagine: they are used in laundries, in theatre wardrobes and large halls, in the back rooms of butcher shops and in the production departments in the food industry.

Italiano

Italiano

简体中文

简体中文